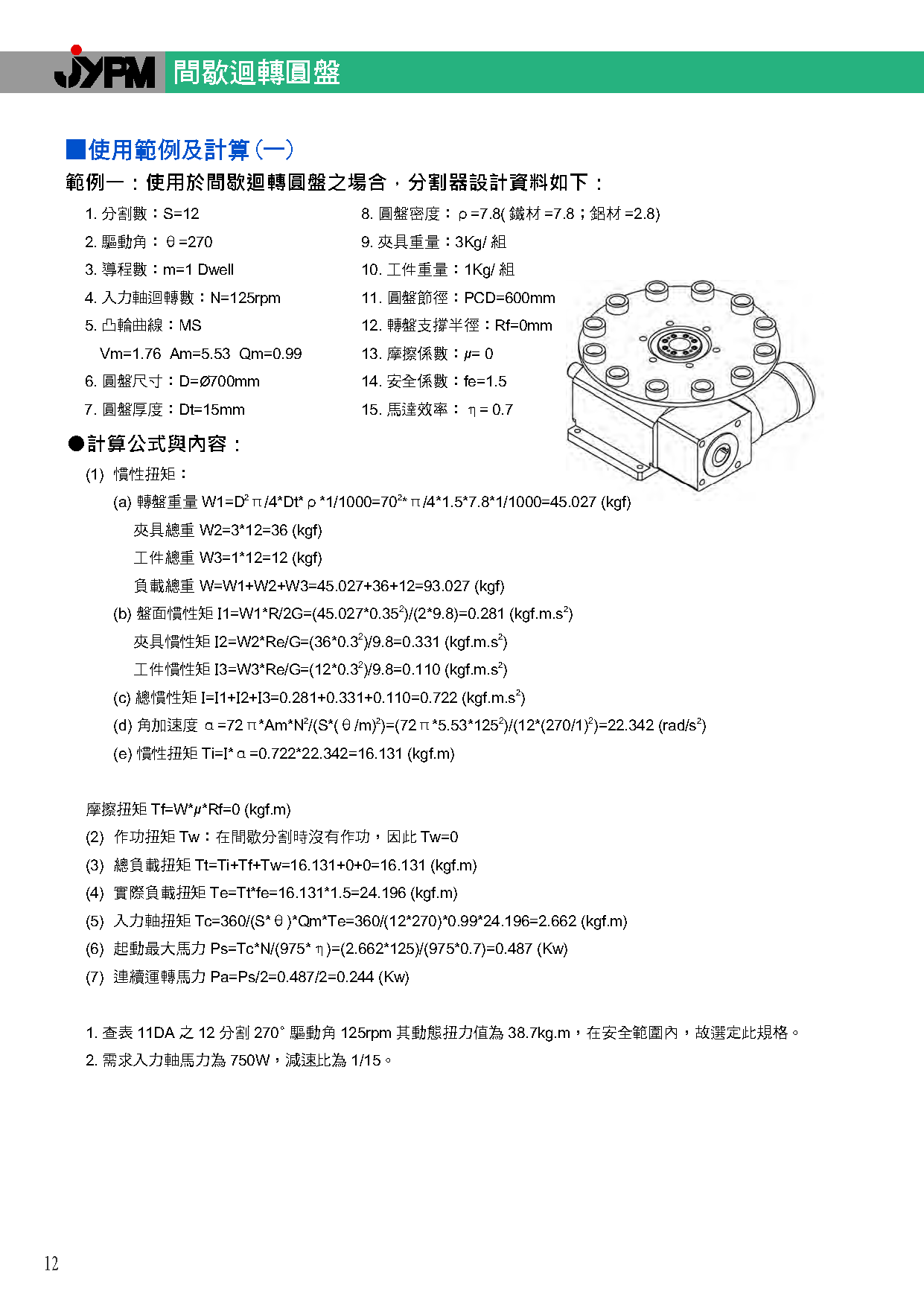

| 分割器选型计算(适用于间歇回转转盘运动) |

|

|

点击这返回总目录 |

| 须知:修改草绿色范围内数值,粉红色的为建议尺寸,可以不用修改;黄色为自动计算尺寸,不得修改; |

|

|

|

|

|

|

| 参 数 输 入 区 |

间歇分割定位等份(N) |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 每分割定位时间(t1) |

1 |

sec |

|

|

|

|

|

|

|

直接结果 |

选择的实际负载Te要大于 |

19.86 |

kg. m |

|

|

|

|

| 每分割驱动时间(t2) |

3 |

sec |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 入力轴回转数(n ) |

125 |

rpm |

|

|

|

|

|

|

|

需要电机功率要大于 |

0.40 |

kw |

|

|

|

|

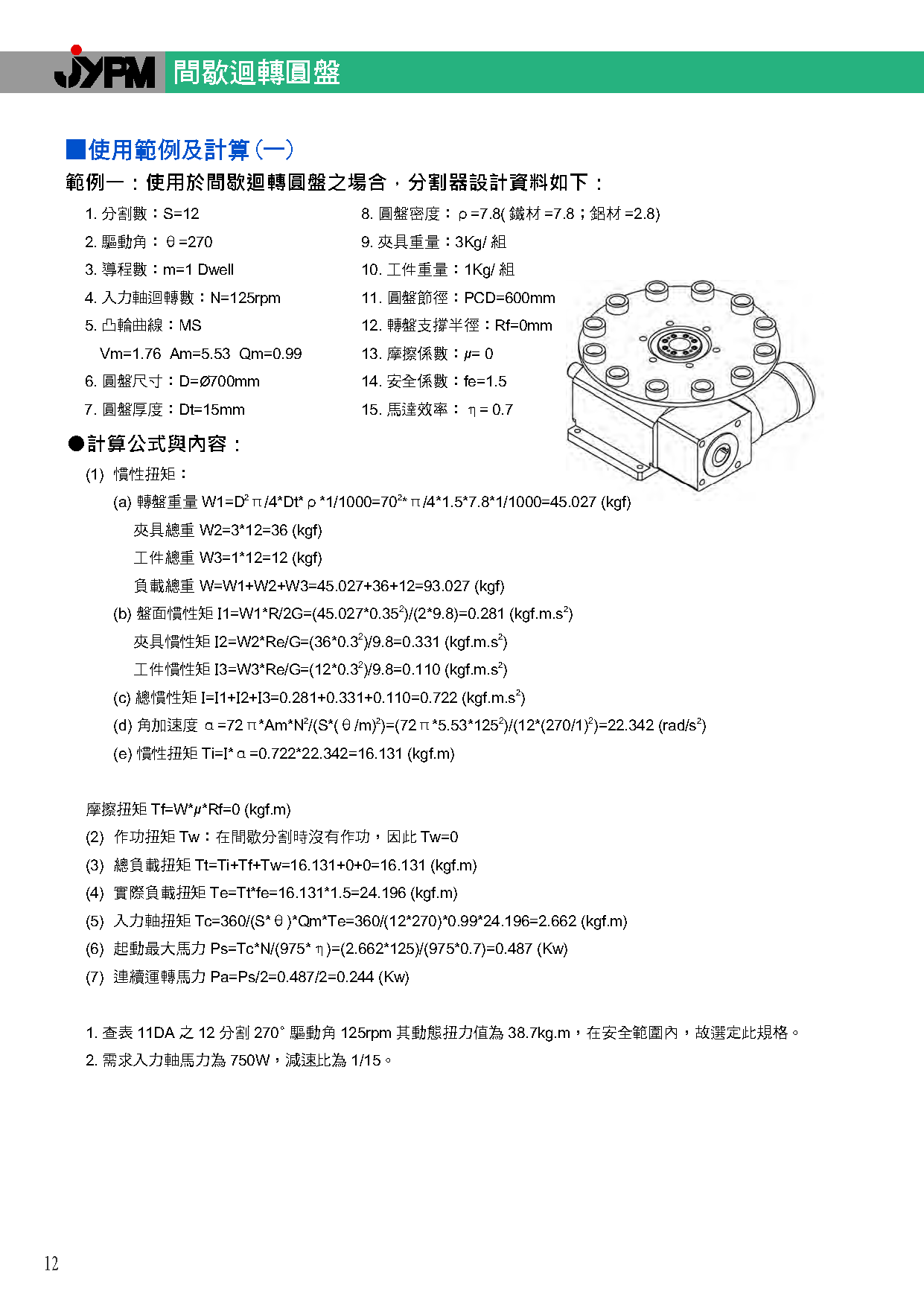

| 回转盘直径(D) |

60 |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 回转盘厚度(T) |

1.5 |

cm |

|

|

|

|

|

|

|

摩擦扭矩 |

0.00 |

HP |

|

|

|

|

| 材质比重(M) |

7.8 |

kg / m^3 |

|

|

|

|

|

|

|

|

|

|

|

|

| 工件重量(M1) |

1 |

kg/组 |

|

|

|

|

|

|

|

静扭矩(惯性扭矩) |

13.24 |

kg.m |

|

|

|

|

| 夹具重量(M2) |

3 |

kg/组 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

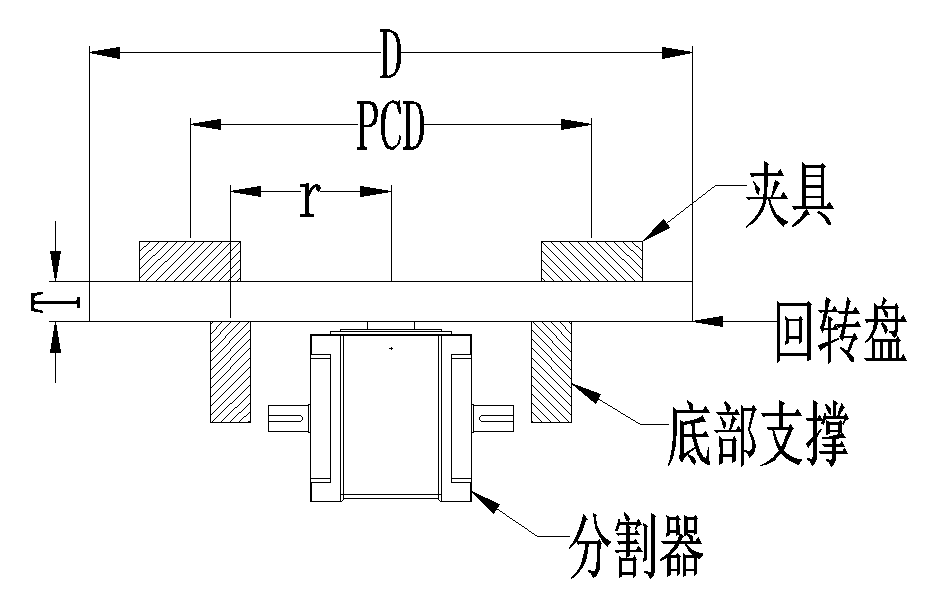

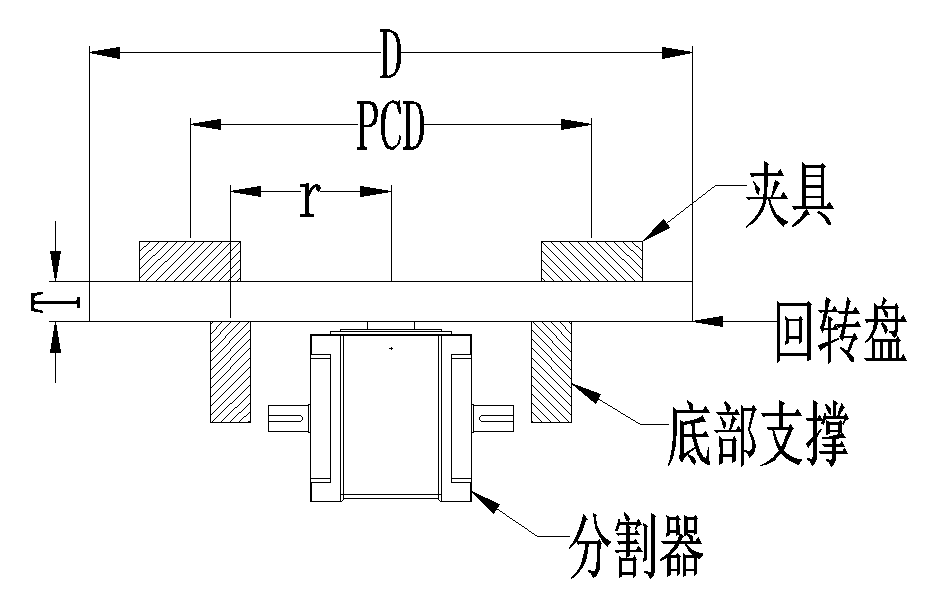

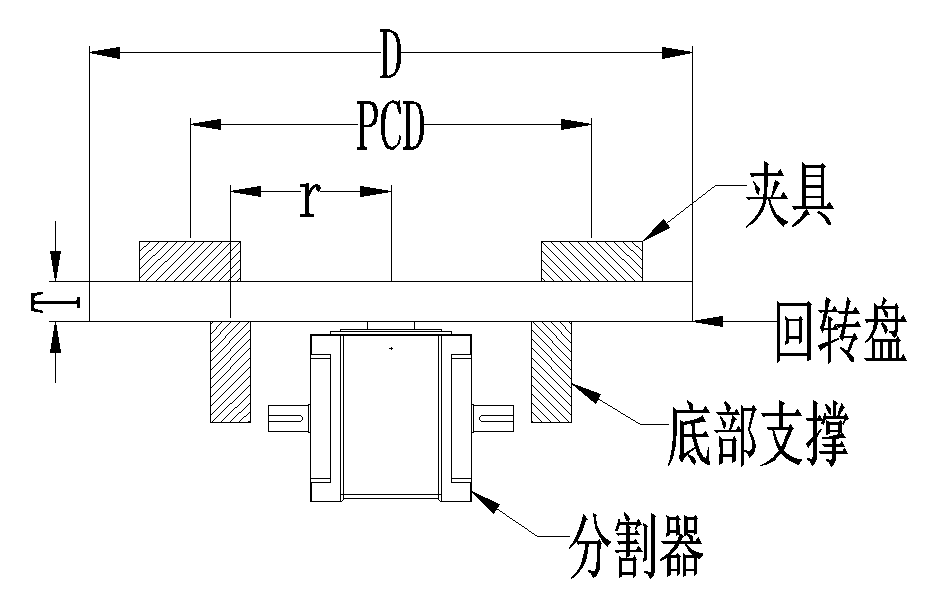

| 转盘底部加支撑时,接触点到转盘中心的有效半径( r ) |

0 |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 夹具固定的节圆半径Re(PCD/2) |

30 |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

摩擦系数u |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

电机效率z |

0.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

安全系数fe |

1.5 |

|

要求高精度时,可修改为2~3; |

|

|

|

|

|

|

|

|

|

|

|

凸轮转位角度【驱动角】(Qh) |

270 |

度 |

驱动角=360°×(驱动时间)/(驱动时间+定位时间) |

|

|

|

|

|

|

|

|

|

|

|

|

凸轮曲线系修正正弦曲线 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(M.S.),因此: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

最大非向性速度……....(Vm) |

1.76 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

最大非向性加速度…....(Am) |

5.53 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

凸轮最大扭力系数…....(Qm) |

0.99 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 以下为自动计算过程: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 质量计算 |

圆盘重量(W1) |

= |

( 3.14159 / 4 ) * D^2 * T * M * 0.1^3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

33.081 |

kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 工件重量(W2) |

= |

工件重量M1*分割等份(N) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

12 |

kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 夹具重量(W3) |

= |

M2 * N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

36 |

kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 零部件惯性矩 |

回转盘惯性矩(I1) |

= |

( W1 * R^2 ) / (2 * G) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

0.1519 |

(kg . m . S^2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 工件惯性矩(I2) |

= |

( W2 * Re^2 ) / G |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

0.1102 |

(kg . m . S^2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 夹具惯性矩(I3) |

= |

( W3 * Re^2 ) / G |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

0.3306 |

(kg . m . S^2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 总惯性矩( I ) |

= |

I1 + I2 + I3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

0.593 |

(kg . m . S^2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 出力轴最大角加速度.(O) |

= |

Am ((2 * 3.1416) / N) * [(360 / Qh) * ( n / 60)]^2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

22.34 |

(rad / S^2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 静扭矩(惯性扭矩)(Ti) |

= |

I * O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

13.24 |

(kg . m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 摩擦扭矩(Tf) |

= |

u * w * R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

0.00 |

(kg . m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 作功扭矩(Tw) 在间歇分割时没有作功,因此 Tw = 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 以上总负载扭矩(Tt) |

= |

Ti + Tf + Tw |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

13.2424 |

(kg . m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 实际负载扭矩(Te) |

= |

Tt*fe |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

19.864 |

(kg . m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 入力轴扭矩Tc |

= |

[360 / (Qh * N)] * Qm * (Te + Tca) |

|

|

入力轴扭矩(Tc) 注:入力轴起动负载扭矩视为0 , 因此 Tca =0 |

|

|

|

|

|

|

|

| = |

2.1850 |

(kg . m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 所须要的电机参数(P) |

= |

( Tc * n ) / (716 * Z) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| = |

0.545 |

(HP) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

或 (P) |

= |

( Tc * n ) / (975 * Z) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

= |

0.400 |

(kw) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

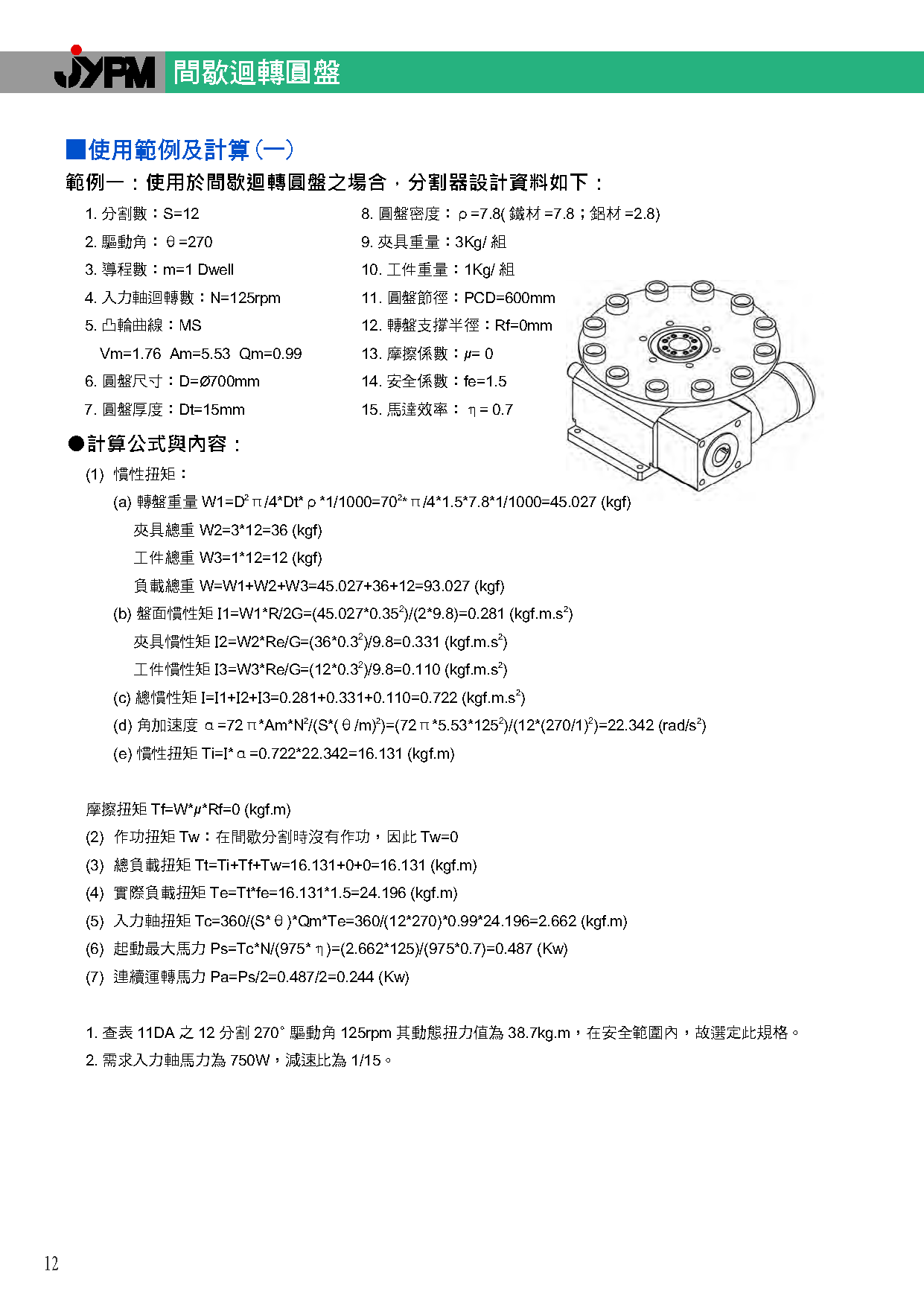

| 选型案例(兆奕分割器): |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|